Fusion Power (EPSRC CDT)

About the course

The Fusion Power (EPSRC CDT) is a research-based course combining training and research in fusion-relevant fields like plasma physics, materials science, and computational modelling, with initial taught modules followed by a major research project.

The Fusion Power Centre for Doctoral Training (CDT) is provided by a collaboration between six UK universities (Durham, Liverpool, Manchester, Oxford, Sheffield, and York), other research organisations including Culham Centre for Fusion Energy, and industry such as Tokamak Energy, First Light Fusion and OxfordSigma.

You will be trained to doctoral-level (a PhD is known as a DPhil at Oxford) in disciplines related to fusion power. A significant number of fully-funded four-year full-time and eight-year part-time doctoral studentships are expected to be available each year. The CDT expects to train at least 80 students over five intakes from 2024 to 2028.

You will train and study alongside students undertaking the DPhil in Materials, together forming an Oxford cohort of research students in materials. The majority of projects are expected to collaborate with the wider fusion industry. In Oxford, students will focus on materials for fusion power.

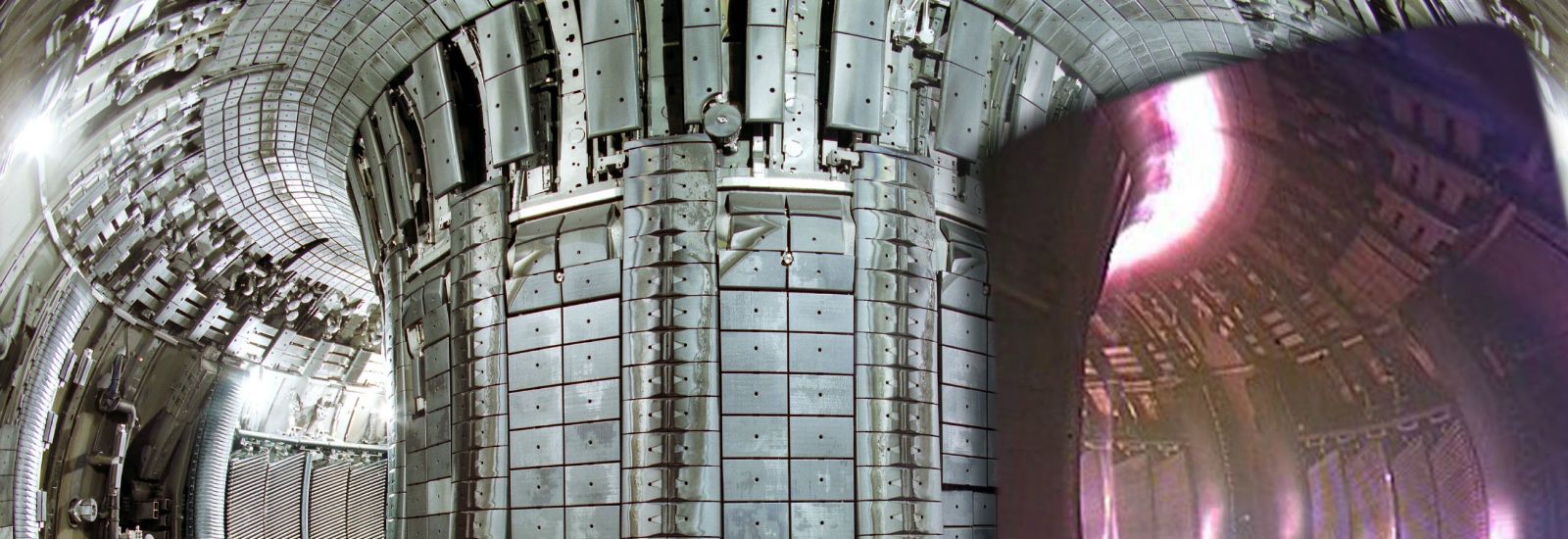

The plasma-facing components, magnets and breeding blanket of any future fusion tokamak will be subjected to some of the most extreme engineering environments possible, with high temperatures, stresses and extreme levels of radiation damage. For fusion to be feasible as an economic power source, the materials used must be able to survive these conditions, retaining usable thermal and mechanical properties, for five years or more. Fusion CDT projects in Oxford will work on solving these challenges and making fusion a reality.

You will have access to a range of fusion materials facilities within Oxford and across the UK, and international links provide access to many other fusion devices around the world.

The combination of world-leading experts and world-class facilities creates an outstanding training environment for the next generation of fusion scientists - the generation who may exploit STEP, ITER, NIF and other international experiments to make fusion energy a reality.

Course structure

An overview of the course structure is provided below. Details of the compulsory elements of the course are provided in the Course components section of this page.

The course is normally carried out in four years of full-time study (or eight years of part-time study) under the supervision of an experienced member of staff. The first year (first two years for if you are studying part-time) will be focused on training. All students are registered at the University of Oxford.

If studying full-time, you will spend the first eight months of the course (the first 16 months if studying part-time), attending a number of intensive one-week or two-week technical fusion modules designed to provide the best possible platform for your substantial research project. Please note that the modules offered may change to reflect the latest academic thinking and expertise of staff.

During your first year if studying full-time (your first two years if studying part-time) , you will also attend 'Frontiers of Fusion and Interfaces', an annual workshop which features fascinating talks by well-known and internationally-respected external speakers. Students from all cohorts (and their supervisors) will gather for a scientific meeting exploring a range of fusion issues and how they link to related fields, such as fission, advanced instrumentation, technological plasmas, and more.

The remaining three years of the full-time course (six years if studying part-time) will be spent conducting research.

To learn more about the research topics you’ll have the opportunity to explore, please refer to the Research areas section on this page.

Attendance

The course can be studied full-time or part-time with both modes requiring attendance in Oxford. Full-time students are subject to the University's Residence requirements. Part-time students are required to attend course-related activities in Oxford for a minimum of 30 days each year.

The full-time course is usually studied over four years. The part-time course is usually studied over eight years.

These intensive one-week or two-week technical fusion modules are run by all six partners and will be taught at the other collaborating universities, with periods in between courses spent in Oxford completing the course work assignments. Travel and subsistence funds are provided for attending the different modules.

Provision exists for students on some courses to undertake their research in a ‘well-founded laboratory’ outside of the University. This may require travel to and attendance at a site that is not located in Oxford. Where known, existing collaborations will be outlined on this page. Please read the course information carefully, including the additional information about course fees and costs.

Resources to support your study

As a graduate student, you will have access to the University's wide range of resources including libraries, museums, galleries, digital resources and IT services.

The Bodleian Libraries is the largest library system in the UK. It includes the main Bodleian Library and libraries across Oxford, including major research libraries and faculty, department and institute libraries. Together, the Libraries hold more than 13 million printed items, provide access to e-journals, and contain outstanding special collections including rare books and manuscripts, classical papyri, maps, music, art and printed ephemera.

The University's IT Services is available to all students to support with core university IT systems and tools, as well as many other services and facilities. IT Services also offers a range of IT learning courses for students to support with learning and research, as well as guidance on what technology to bring with you as a new student at Oxford.

The department has excellent and wide-ranging research resources including:

- a world-class suite of electron microscopy facilities including analytical STEMs and TEMs, three FIBs and two ultrahigh resolution SEMs optimised for EBSD and EDX analysis, together with a number of supporting and training instruments. Much of this equipment is installed in the David Cockayne Centre for Electron Microscopy;

- additional electron microscopy facilities are available at the national electron Physical Science Imaging Centre;

- extensive further facilities for characterising materials including, for example, AFM, XPS, and Raman microscopy;

- clean room facilities;

- nanomechanical characterisation equipment;

- special processing or manufacturing facilities for polymers, ceramics, carbon nanomaterials, rapidly solidified materials and devices such as novel batteries or superconductors;

- superb facilities for 3-D atom probe analysis (including LEAP 5000XS and LEAP 5000XR);

- an alloy processing and mechanical properties laboratory, for aerospace and nuclear materials; and

- a wide range of specialist modelling software and if appropriate for your research project, access to Oxford's Advanced Research Computing facilities.

In addition to the excellent central and college library provision, there is a specialist Materials Science Library housed within the department.

Supervision

The allocation of graduate supervision for this course is the responsibility of the Department of Materials and it is not always possible to accommodate the preferences of incoming graduate students to work with a particular member of staff. Under exceptional circumstances a supervisor may be found outside the Department of Materials.

Typically, you will have the opportunity to meet with your supervisor approximately every two to three weeks.

Assessment

All students will be initially admitted to the status of Probationer Research Student (PRS). Normally after six terms as a full-time PRS student, and 12 terms as a part-time PRS students, you will be expected to apply for transfer of status from Probationer Research Student to DPhil status.

A successful transfer of status from PRS to DPhil status will require completion of the taught aspects of the Fusion Power course and a report on the first months of work on your DPhil project.

If successful at transfer, you will also be expected to apply for and gain confirmation of DPhil status within ten terms of admission (within 20 terms if studying part-time), to show that your work continues to be on track.

Both milestones normally involve an interview with at least two assessors (other than your supervisor) and therefore provide important experience for the final oral examination.

You will be expected to submit a substantial thesis after four years from the date of admission if studying full-time (eight years if part-time). To be successfully awarded a DPhil you will need to defend your thesis orally (viva voce) in front of two appointed examiners.

Graduate destinations

There are a number of careers open to Fusion Power graduates and, more generally, Oxford materials graduates are highly regarded by a wide range of employers, including universities, national laboratories in the UK and abroad, high-tech start-up companies, engineering consultancies, industry (including aerospace, electronics, automotive, steel manufacture, medical and household products sectors), world-famous technology companies, schools and colleges, and the financial and business sectors.

Changes to this course

The University will seek to deliver this course in accordance with the description set out in this course page. However, there may be situations in which it is desirable or necessary for the University to make changes in course provision, either before or after registration. The safety of students, staff and visitors is paramount and major changes to delivery or services may have to be made if a pandemic, epidemic or local health emergency occurs. In addition, in certain circumstances, for example due to visa difficulties or because the health needs of students cannot be met, it may be necessary to make adjustments to course requirements for international study.

Where possible your academic supervisor will not change for the duration of your course. However, it may be necessary to assign a new academic supervisor during the course of study or before registration for reasons which might include illness, sabbatical leave, parental leave or change in employment.

For further information please see our page on changes to courses and the provisions of the student contract regarding changes to courses.

Course components

If studying full-time, you will spend the first eight months of the course (the first 16 months if studying part-time), attending a number of technical fusion modules designed to provide the best possible platform for your substantial research project. Please note that the modules offered may change to reflect the latest academic thinking and expertise of staff. Some examples of modules include:

- Introduction to Fusion Plasmas

- Introduction to Materials

- Plasma Facing Technologies

- Irradiation Damage and Degradation

- Leadership and Research skills

- Tritium and the Fusion Fuel Cycle

- Plasma Surface Interactions Lab

- Functional and Superconducting Technologies

- Data Management and Software Skills

- Analytical Tools for Fusion Materials

- Manufacturing and Design Codes

- Multi-scale Computational materials engineering.

These intensive one-week or two-week modules are run by all six partners and will be taught at the other collaborating universities, with periods in between courses spent in Oxford completing the course work assignments.

During your first year (your first two years if studying part-time), you will also attend 'Frontiers of Fusion and Interfaces', an annual workshop which features fascinating talks by well-known and internationally-respected external speakers.

While first year of the course (two years if studying part-time) will be focused on training, the remaining three years of the course (six years if studying part-time) will be spent conducting research.

Research areas

You’ll have the opportunity to undertake research within the specialised themes of this course, which include:

- the characterisation of materials, where there is emphasis on electron microscopy and related techniques associated with radiation damage;

- processing and manufacturing of new materials for fusion;

- modelling of materials, where there is attention to both structures and processes;

- properties of materials needed to realise fusion; and

- development and understanding of functional materials such as tritium breeding ceramics or superconducting materials.

Much of this world-leading research is carried out in close collaboration with industry. Research interests in Oxford's Department of Materials extend over most branches of materials science, as well as some aspects of solid-state physics and chemistry. These include the study of a wide range of materials of relevance in advanced technological applications.

The University offers a range of projects, both experimental and modelling, on the processing, joining, microstructure, mechanical properties, and resistance to radiation damage of these materials. Projects will use a range of specialised research techniques, usually in combination:

- advanced processing, coating and joining methods (mechanical alloying, rapid solidification, spray forming, additive manufacture, friction-stir welding);

- irradiation of materials by high-energy ion-beams, protons and neutrons;

- liquid metal corrosion;

- characterisation of superconducting materials;

- electron microscopy of microstructures, and radiation damage effects, including in-situ irradiations, and field-ion microscopy of radiation damage;

- microanalysis by atom-probe tomography and electron-optical methods;

- X-ray diffraction including use of the diamond light source mechanical testing, including micromechanics, over a wide temperature range; and

- computer modelling of radiation damage effects, deformation and microstructural development.

Further information

Information about potential research projects can be found on the department's website (under Fusion Power projects), along with information about research in the department.

Entry requirements for entry in 2026-27

Proven and potential academic excellence

The requirements described below are specific to this course and apply only in the year of entry that is shown. You can use our guidance to help you evaluate whether your application is likely to be competitive.

Please be aware that any studentships that are linked to this course may have different or additional requirements and you should read any studentship information carefully before applying.

Degree-level qualifications

As a minimum, applicants should hold or be predicted to achieve the following UK qualifications or their equivalent:

- a first-class or strong upper second-class undergraduate degree with honours in a suitable science subject such as materials science, chemistry, physics, or mathematics.

Other subjects may be acceptable depending on the area of research chosen.

For candidates offering a UK bachelor's degree or UK integrated undergraduate master's degree normally we require an overall grade of at least 65%. As examples of international equivalents to this requirement: for the US system we normally regard a GPA of 3.5 to 3.6 out of 4.0 on a four-year bachelor's course as equivalent and for the Chinese system we normally regard an overall degree mark of 85% on a four-year bachelor's degree course from a Double First-Class University, Project 985 or Project 211 institution as equivalent.

If your degree is not from the UK or another country specified above, visit our International Qualifications page for guidance on the qualifications and grades that would usually be considered to meet the University’s minimum entry requirements.

Normally the required qualification(s) must be achieved by the date of commencement of the research course for which you have applied.

GRE General Test scores

No Graduate Record Examination (GRE) or GMAT scores are sought.

Other qualifications, evidence of excellence and relevant experience

Additional indicators that will be considered when assessing your application against the department's criteria include your performance in previous research project(s), the award of national prizes, the award of substantial scholarships, preliminary knowledge of relevant research techniques, and your suitability for the research projects in which you have expressed interest.

The criteria against which your written application and interview will be assessed are:

- Appropriate indicators of proven and/or potential: academic excellence, research excellence, originality, ability to absorb new ideas, reasoning ability, creativity of thought, initiative, and capacity for sustained and intense work;

- sufficient evidence, in the view of the assessors, to suggest that you have the academic ability, motivation and commitment to (i) pursue the chosen research programme to a successful conclusion within the required time limits, and (ii) to pursue research in the subject of materials at a high level;

- the programme of study, including research topic, that you wish to pursue is well suited to your academic interests and abilities to which you/your referees have drawn attention in the application. For some projects this may include the ability to work as part of a team; and

- sufficient evidence of ability to (i) engage in a scientific or technical discussion in English at a satisfactory level, both verbally and in writing, (ii) understand a reasoned case presented in English and (iii) present a reasoned case in English.

Publications are not essential but will be taken into account. Please include details of any publications you may have in peer-reviewed international journals in the relevant field of the application form which you will find in the Qualifications and experience section.

English language proficiency

This course requires proficiency in English at the University's standard level. If your first language is not English, you may need to provide evidence that you meet this requirement. The minimum scores required to meet the University's standard level are detailed in the table below.

| Test | Minimum overall score | Minimum score per component |

|---|---|---|

| IELTS Academic (Institution code: 0713) | 7.0 | 6.5 |

| TOEFL iBT* including the 'Home Edition' (Institution code: 0490) | 100 | Listening: 22 Reading: 24 Speaking: 25 Writing: 24 |

| C1 Advanced† | 185 | 176 |

| C2 Proficiency‡ | 185 | 176 |

| Oxford Test of English Advanced | 155 | 145 |

*Changes to the TOEFL iBT test are being introduced on 21 January 2026. If you are taking a TOEFL test after this date, please note that these changes may affect whether the University is able to accept this test.

†Previously known as the Cambridge Certificate of Advanced English or Cambridge English: Advanced (CAE)

‡Previously known as the Cambridge Certificate of Proficiency in English or Cambridge English: Proficiency (CPE)

Your test must have been taken no more than two years before the start date of your course. Our Application Guide provides further information about the English language test requirement.

Declaring extenuating circumstances

If your ability to meet the entry requirements has been affected by the COVID-19 pandemic (eg you were awarded an unclassified/ungraded degree) or any other exceptional personal circumstance (eg other illness or bereavement), please refer to the guidance on extenuating circumstances in the Application Guide for information about how to declare this so that your application can be considered appropriately.

References

You will need to register three referees who can give an informed view of your academic ability and suitability for the course. The How to apply section of this page provides details of the types of reference that are required in support of your application for this course and how these will be assessed.

Supporting documents

You will be required to supply supporting documents with your application. The How to apply section of this page provides details of the supporting documents that are required as part of your application for this course and how these will be assessed.

Performance at interview

Interviews are normally held as part of the admissions process.

These interviews will usually be conducted online. Shortlisting for interview is carried out according to the criteria included in the present entry requirements as judged from your submitted application (including your references).

If you are applying for part-time study and invited to attend an interview, you may be asked about your ability to commit sufficient time to study and fulfil all elements outlined in the course description (eg completing coursework, assessments, and attending course and University events and modules).

Offer conditions for successful applications

If you receive an offer of a place at Oxford, your offer will outline any conditions that you need to satisfy and any actions you need to take, together with any associated deadlines. These may include academic conditions, such as achieving a specific final grade in your current degree course. These conditions will usually depend on your individual academic circumstances and may vary between applicants. Our 'After you apply' pages provide more information about offers and conditions.

In addition to any academic conditions which are set, you will also be required to meet the following requirements:

Financial Declaration

If you are offered a place, you will be required to complete a Financial Declaration in order to meet your financial condition of admission.

Disclosure of criminal convictions

In accordance with the University’s obligations towards students and staff, we will ask you to declare any relevant, unspent criminal convictions before you can take up a place at Oxford.

Academic Technology Approval Scheme (ATAS)

This course may require you to obtain an ATAS certificate before you can apply for a visa/immigration permission. If you are offered a place, the academic department will confirm whether an ATAS certificate is required. If so, they will also send you the information you need to apply for one. You can apply for ATAS whilst your offer is conditional and before the Confirmation of Acceptance for Studies (CAS) is issued. Further information about ATAS is available on the student visa webpages.

Other factors governing whether places can be offered

The following factors will also govern whether candidates can be offered places:

- the ability of the University to provide the appropriate supervision for your studies, as outlined under the 'Supervision' heading in the About section of this page;

- the ability of the University to provide appropriate support for your studies (eg through the provision of facilities, resources, teaching and/or research opportunities); and

- minimum and maximum limits to the numbers of students who may be admitted to the University's taught and research programmes.

Funding

For this course, we recommend that you visit our dedicated funding pages which include details of a range of external funding and loan schemes for postgraduate study. Some scholarships may also be available through our fees, funding and scholarship search tool. You should review the information carefully, including the eligibility criteria and application deadlines, noting that not all funding opportunities are available for postgraduate diploma and postgraduate certificate courses.

Details of college-specific funding opportunities can also be found on individual college websites:

Please refer to the College preference section of this page to identify which of the colleges listed above accept students for this course.

For the majority of college scholarships, it doesn’t matter which college, if any, you state a preference for in your application. If another college is able to offer you a scholarship, your application can be moved to that college if you accept the scholarship. Some college scholarships may require you to state a preference for that college when you apply, so check the eligibility requirements carefully.

Costs

Annual course fees for the 2026-27 academic year at the University of Oxford

The fees for this course are charged on an annual basis.

Full-time study

Part-time study

What do course fees cover?

Course fees cover your teaching as well as other academic services and facilities provided to support your studies. Unless specified in the additional information section below, course fees do not cover your accommodation, residential costs or other living costs. They also don’t cover any additional costs and charges that are outlined in the additional costs information below.

How long do I need to pay course fees?

Course fees are payable each year, for the duration of your fee liability (your fee liability is the length of time for which you are required to pay course fees). For courses lasting longer than one year fees will usually increase annually, as explained in the University’s Terms and Conditions.

Graduate students who have reached the end of their standard period of fee liability will be required to pay a University continuation charge and/or a college continuation charge.

The University continuation charge, per term for entry in 2026-27 is £656, please be aware that this will increase annually. For part-time students, the termly charge will be half of the termly rate payable by full-time students.

If a college continuation charge applies (not applicable for non-matriculated courses) it will be between £150 and £500, as explained in our information about continuation charges. Please contact your college for more details, including information about whether your college's continuation charge is applied at a different rate for part-time study.

Where can I find more information about fees?

Our fees and other charges pages provide further information, including details about:

- course fees and fee liability;

- how your fee status is determined;

- changes to fees and other charges; and

- continuation charges.

Information about how much fees and other costs will usually increase each academic year is set out in the University's Terms and Conditions.

Additional costs

Full-time study

Part-time study

Living costs

In addition to your course fees and any additional course-specific costs, you will need to ensure that you have adequate funds to support your living costs for the duration of your course.

Living costs for full-time study

For the 2026-27 academic year, the range of likely living costs for a single, full-time student is between £1,405 and £2,105 for each month spent in Oxford. We provide the cost per month so you can multiply up by the number of months you expect to live in Oxford. Depending on your circumstances, you may also need to budget for the costs of a student visa and immigration health surcharge and/or living costs for family members or other dependants that you plan to bring with you to Oxford (if dependant visa eligibility criteria are met).

Living costs for part-time study

Your living costs may vary depending on your personal circumstances but you will still need to cover your cost of living on a full-time basis for the duration of your course, even if you will not be based in Oxford throughout your studies. While the range of likely living costs for a single, full-time student living in Oxford in the 2026-27 academic year is between £1,405 and £2,105 per month, living costs outside Oxford may be different.

Part-time students who are not based in Oxford will need to calculate travel and accommodation costs carefully. Depending on your circumstances and study plans, this may include the cost of a visitor visa to attend for short blocks of time (if visitor visa eligibility criteria are met).

Further information about living costs

The current economic climate and periods of high national inflation in recent years make it harder to estimate potential changes to the cost of living over the next few years. For study in Oxford beyond the 2026-27 academic year, it is suggested that you budget for potential increases in living expenses of around 4% each year – although this rate may vary depending on the national economic situation.

A breakdown of likely living costs for one month during the 2026-27 academic year are shown below. These costs are based on a single, full-time graduate student, with no dependants, living in Oxford.

| Lower range | Upper range | |

|---|---|---|

| Food | £315 | £545 |

| Accommodation | £825 | £990 |

| Personal items | £160 | £310 |

| Social activities | £50 | £130 |

| Study costs | £35 | £90 |

| Other | £20 | £40 |

| Total | £1,405 | £2,105 |

For information about how these figures have been calculated as well as tables showing the likely living costs for nine and twelve months, please refer to the living costs page of our website.

Colleges

Students enrolled on this course will belong to both a department/faculty and a college. Please note that ‘college’ and ‘colleges’ refers to all 43 of the University’s colleges, including those designated as societies and permanent private halls (PPHs).

If you apply for a place on this course you will have the option to express a preference for one of the colleges listed below, or you can ask us to find a college for you. Before deciding, we suggest that you read our brief introduction to the college system at Oxford and our advice about expressing a college preference.

If you are a current Oxford student and you would like to remain at your current Oxford college, you should check whether it is listed below. If it is, you should indicate this preference when you apply. If not, you should contact your college office to ask whether they would be willing to make an exception. Further information about staying at your current college can be found in our Application Guide.

Full-time study

The following colleges accept students for full-time study on this course:

Part-time study

The following colleges accept students for part-time study on this course:

Before you apply

Our guide to getting started provides general advice on how to prepare for and start your application, including advice to help you evaluate whether your application is likely to be competitive.

If it is important for you to have your application considered under a particular deadline – eg under the January deadline in order to be considered for Oxford scholarships – we recommend that you aim to complete and submit your application at least two weeks in advance. Check the deadlines on this page and the information about deadlines and when to apply in our Application Guide.

Application fee waivers

An application fee of £20 is payable for each application to this course. Application fee waivers are available for the following applicants who meet the eligibility criteria:

- applicants from low-income countries;

- refugees and displaced persons;

- UK applicants from low-income backgrounds; and

- applicants who applied for our Graduate Access Programmes in the past two years and met the eligibility criteria.

You are encouraged to check whether you're eligible for an application fee waiver before you apply.

Readmission for current Oxford graduate taught students

If you're currently studying for an Oxford graduate taught course and apply to this course with no break in your studies, you may be eligible to apply to this course as a readmission applicant. The application fee will be waived for an eligible application of this type. Check whether you're eligible to apply for readmission.

Application fee waivers for eligible associated courses

If you apply to this course and up to two eligible courses during the same application cycle, you can request an application fee waiver so that you only need to pay one application fee. We recommend that you use your application fee waiver to apply only for eligible courses that are closely related in research area to this one.

To be considered eligible for an application fee waiver, each additional course must be:

- doctoral level eg a Doctor of Philosophy (DPhil) or Centre for Doctoral Training (CDT) course; and

- offered by one of the departments in the MPLS Division or one of the departments in the Medical Sciences Division.

If this is the first eligible course that you are applying to, you can request an application fee waiver for an additional course after you have submitted your application for this course. If you have already applied to another course that the meets the eligibility criteria shown above, you should request an application fee waiver before starting an application to this course.

Remember to state clearly in your request which course(s) you intend to apply to. If your request is successful, you will receive an application fee waiver code that is valid for this admission cycle (ie for entry in the 2026-27 academic year). Our Application Guide provides instructions for entering your application fee waiver code.

Do I need to contact anyone before I apply?

There is no need to contact any supervisor before making an application. Details of all projects being offered that are suitable can be found on the Department of Materials website under Fusion Power CDT.

Completing your application

You should refer to the information below when completing the application form, paying attention to the specific requirements for the supporting documents.

If any document does not meet the specification, including the stipulated word count, your application may be considered incomplete and not assessed by the academic department. Expand each section to show further details.

Proposed field and title of research project

You are not required to complete this field of the application form. Instead, you are required to list up to four projects from the department's website that you are interested in applying to, in order of preference, as part of your Statement of purpose/Personal statement (see below).

You should not use this field to type out a full research proposal. You will be able to upload your research supporting materials separately if they are required (as described below).

Proposed supervisor

You should list all of the supervisors' names that are associated with the projects (up to four) that you are interested in, and will be listed in your Statement of purpose/Personal statement (see below).

Referees:

Three overall, of which at least two must be academic

Whilst you must register three referees, the department may start the assessment of your application if two of the three references are submitted by the course deadline and your application is otherwise complete. Please note that you may still be required to ensure your third referee supplies a reference for consideration.

It is desirable that one of your references is from an academic staff member who has supervised you in a research project.

If you are a current master’s student or have completed a master’s course, one of your referees should be your supervisor or course director on this course. If you do not provide a reference from your master’s supervisor or course director, the department will usually ask you to do so before completing the assessment of your application.

Normally at least two of your references should be from academic staff members who taught or supervised you during your bachelor’s and/or master’s degree programmes. The primary purpose of the three references is to provide the department with evidenced insight into your potential to excel as a research student.

Official Transcripts

Your transcripts should give detailed information of the individual grades received in your university-level qualifications to date. You should only upload official documents issued by your institution and any transcript not in English should be accompanied by a certified translation.

More information about the transcript requirement is available in the Application Guide.

CV/résumé

A CV/résumé is compulsory for this course. Most applicants choose to submit a document of one to two pages highlighting their academic achievements and any relevant professional experience.

Statement of purpose:

400 words, accompanied by a list of preferred projects and supervisors

A detailed research proposal is not required. Instead, you should provide a single document comprising both:

- a list of up to four research projects (and the associated supervisors) in which you are interested, in order of preference, selected from the subset of currently advertised projects on the department's website and being identified as suitable for the Fusion Power CDT; and

- an outline of your research interests, written in English, that clearly indicates the rationale behind your choice of projects. Please be sure to also include all of the supervisor(s) name(s) in the supervisors field of the application form. However, there is no need to repeat the project titles in the research project field of the application form.

Start or continue your application

You can start or return to an application using the relevant link below. As you complete the form, please refer to the requirements above and consult our Application Guide for advice.

Apply - Full time Apply - Part time Continue application

After you've submitted your application

Your application (including the supporting documents outlined above) will be assessed against the entry requirements detailed on this course page. Whether or not you have secured funding will not be taken into consideration when your application is assessed. You can find out more about our shortlisting and selection process in our detailed guide to what happens next.

Find out how to manage your application after submission, using our Applicant Self-Service tool.