Oxford bake-off starts

A social anthropologist from Oxford University is collaborating with Japanese and UK potters in building and firing two traditional kilns in Wytham Woods near Oxford. Dr Robin Wilson, an associate researcher from the School of Anthropology and Museum Ethnography, is studying how a traditional craft can remain commercially successful in a modern global economy. The 11-metre-long anagama kiln, fashioned from willow and clay, was lit today.

The anagama kiln or ‘cave’ kiln is being fuelled by eight tonnes of hard and soft wood, sustainably sourced from Wytham Woods. It will build up heat over three days to bake 200 pots at an optimum heat of 1150 degrees Celsius over five days. The fires inside will be stoked around the clock and a number of volunteers have already signed up to help. At its height, the kiln promises to look like a large dragon with flames and smoke billowing out holes along the sides. The public are invited to see it for themselves at a family event starting at noon on Saturday.

Anagama kilns were first used in Korea in the 6th century and later adopted by the Japanese. They largely disappeared in the 17th century, apart from in the province of Bizen which is still famous for its stoneware today. A team of the best potters from Bizen has been flown to Oxford to assist with the making and loading of pots.

The University’s Pitt Rivers Museum has an interest in the research project as it will provide information and context about the processes involved in making some of the artefacts it displays. One research question is: 'What is an "authentic" Japanese pot and how does it compare with an "authentic" British pot?'.

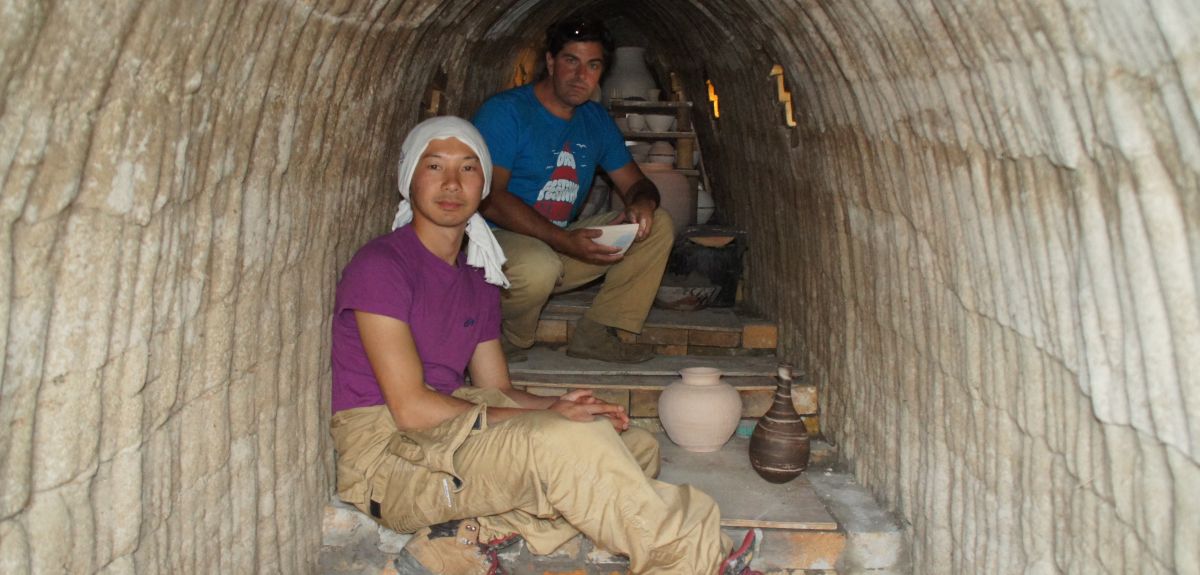

There are few wood-fuelled kilns in the world because of the large amount of timber needed to feed them, but Wytham Woods offers a model for good woodland management.The anagama kiln is constructed from a willow frame overlaid with a layer of clay which is left to dry for one month. The brick kiln was built by the team from Bizen and it is hoped it will remain as a community resource for individuals, as well as pottery groups or schools in the UK for some 25 years.

Project leader Dr Robin Wilson said: 'The social aspect of this craft is a fascinating area of study. Traditionally, a whole Japanese village would have made the pots and then found the wood, chopped it and sat around the communal kiln, keeping one another awake to stoke the fires. We are recreating that communal experience but will leave behind a permanent resource for potters and community groups to use. We are interested in the process of firing pottery using traditional methods. We will see how the Japanese culture differs and combines with the British pottery tradition. We also have a researcher who will look at the geochemistry of blending different British clays, while another is examining the flame dynamics inside the kiln.'

One of Britain’s best known potters, Jim Keeling, founder of Whichford Pottery in Warwickshire, is co-director and has been a driving force behind the project. Its patron is 80-year-old Isezaki Jun, designated the Living National Treasure of Bizen by the Japanese Government and highly venerated in Japan. His former apprentice, Kazuya Ishida, who has produced many of the pots for the project, is at the first firing and is the chief kiln loader. He has had the job of crawling through the very small kiln entrance to stack up the pots before the fires are lit. The multidisciplinary research project also involves the University’s Pitt Rivers Museum and the Ashmolean Museum, which will stage talks and exhibitions of the fired pots later this year.

Jim Keeling said: 'The Anagama Project is reminding us (British potters) that the simplest technique can sometimes be the most effective and that team work enables us to play with techniques creatively, which is much harder individually. Over the last 100 years we have been very influenced by Japanese ceramics, but this aspect of Japanese ceramics has been relatively neglected in Britain and is an aesthetic that is very well suited to the 21st century as it is powerful and direct. We are also spearheading research into different variants of local clays, which will hopefully produce exciting finishes.'

Lord Hague of Richmond elected as new Chancellor of Oxford University

Lord Hague of Richmond elected as new Chancellor of Oxford University

Sheldonian Series launches with an energetic and open exchange of views on 'Democracy'

Sheldonian Series launches with an energetic and open exchange of views on 'Democracy'

New study reveals the explosive secret of the squirting cucumber

New study reveals the explosive secret of the squirting cucumber

Ethiopian wolves reported to feed on nectar for the first time

Ethiopian wolves reported to feed on nectar for the first time

Professor Anthony Harnden appointed as the new Chair of the MHRA

Professor Anthony Harnden appointed as the new Chair of the MHRA